-40%

Mercruiser Alpha One Generation 1 hydraulic Pump Mercury Bravo

$ 145.19

- Description

- Size Guide

Description

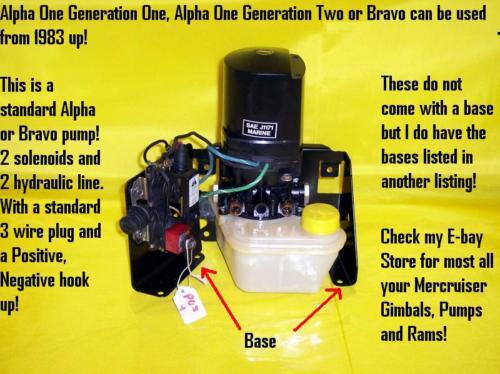

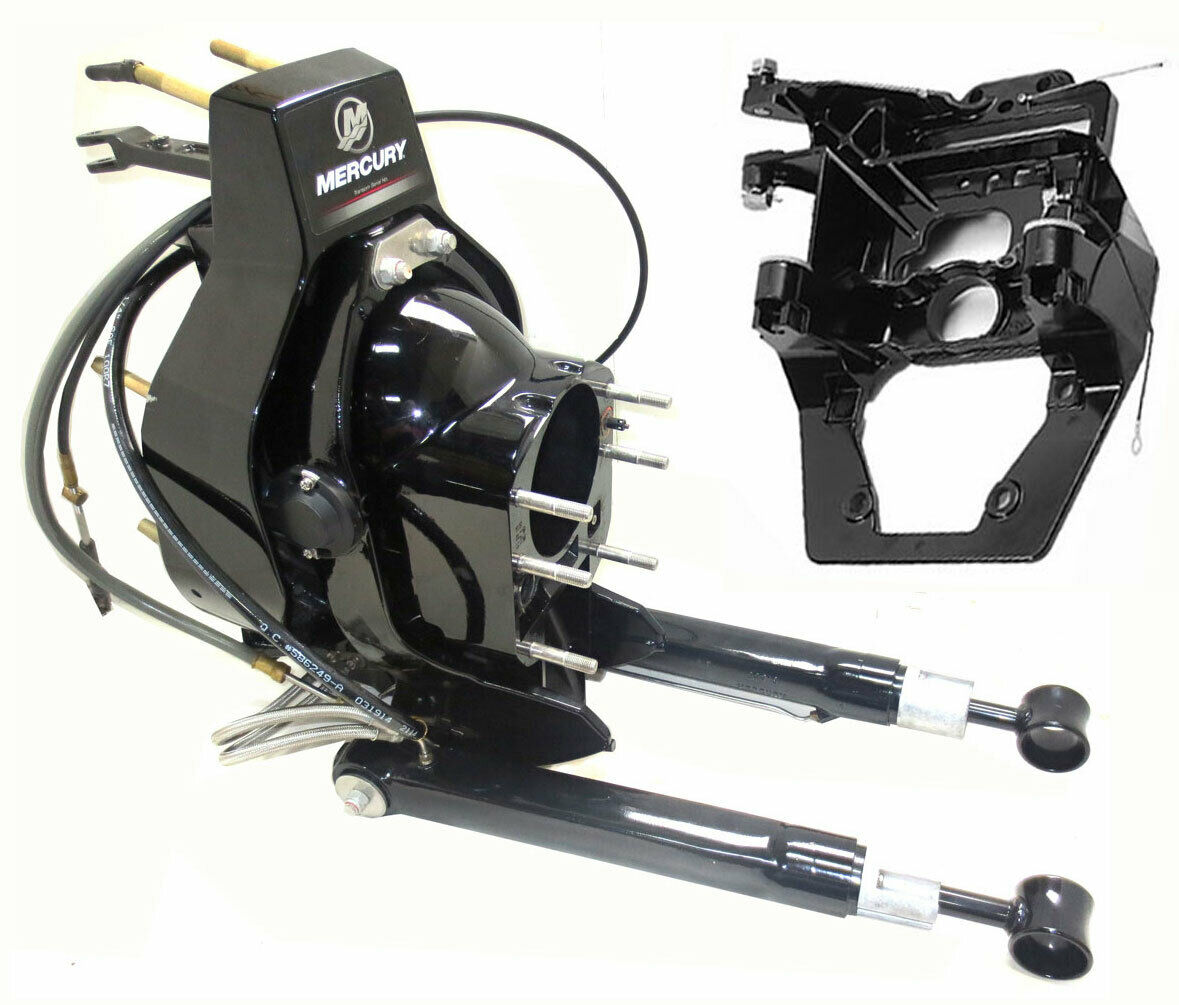

Mercruiser Alpha One Generation 1 Pump Mercury BravoThis sale is for the pump pictured by itself (First Picture) White plastic Reservoir. I will have other pictures of all 3 most common pumps so you can see the differences.

I also have some diagnostics listed below so read on.

And free support if you want to try and fix your existing pump.

This is rebuilt with used clean parts and has 2 year warranty.

The base/floor mount does not come with this pump as most of the time the base is good but I also have these same pumps listed with bases in my e-bay store.

In another listing I have the upgrade kits that you can upgrade from pre-alpha to this Alpha One Generation One style pump.

I also have these listed with a base in my ebay store.

This will run the standard pre-alpha rams or the larger Alpha One Generation One, Alpha One Generation Two or Bravo rams.

The wiring is the same for all Mercruiser and Most Mercury Pumps.

Benefits are faster running, smoother operating, dual solenoids for safer operation.

Tech support is free.

Message me for an international Shipping Quote!

I moved from Florida to Tennessee and started this business, Mikes Alphas.

Payment methods accepted are

Paypal Preferred

Visa / MasterCard

Discover

American Express

Receive payment upon pickup

I also accept credit cards over the phone if you don’t have an online payment method.

Here is some information that might help you diagnose or repair your own pump.

Diagnostics

All Mercruiser & Mercury pumps use the same wiring diagram. This is a simple pattern. The red wires are all positive/hot wires from battery to pump. The black wires are all negative/ground wires. The blue wires are for up like a blue sky and the green wires are for down like green grass. The blue wires go to 1 solenoid for up and if you have 2 solenoids the green wires go to the second solenoid for down.

In 1983 the US coast guard passed a law that all pumps become 2 solenoid pumps mainly for safety. But a second solenoid for down also increases the down speed as a larger wire is used from solenoids to battery (12 Gauge) and then 14 gauge from dash switch to pump. The positive/hot wire should always be fused or a breaker before it hits the pump.

The number J1171 is on all pumps, starters, carburetors, alternators & distributors! This just means it is coast guard approved anti-spark. J1171 is not and I repeat NOT A SERIAL NUMBER! A lot of sellers put this J1171 number in there title and description in hopes that you think it is a serial number and you buy because it is the correct replacement for your boat. Then the seller does not want to accept a return because you bought the wrong pump!

To test a pump motor all you need to do is make sure the black wire has a good ground and run a red test wire to the big blue or green wire that comes out of the motor. If it does not do anything and not even spark then the motor has gone (no contact on brushes). If it sparks then it could be motor or pump is frozen. But either way it is time to replace.

To test solenoids, the big posts are 1 for positive wire and the other big post to a test light that is grounded. The small posts are 1 ground and the other gets a hot wire. The small posts engage the big posts. It does not normally matter which big post is used for positive in or which small post is used for ground.

Cleaning your pumps, you can do it, but do not totally disassemble your pump. There are a lot of tiny washers, check balls, seals & springs that can fly away. Just take the main pump body off the reservoir and clean. I use a spray can of engine degreaser and hot water to rinse. Then I use rubbing alcohol to dissipate the left over moisture before re-assembling.

Never leave your boat stored with outdrive in up position. With the rams up there is less fluid in the pump reservoir and it will cause condensation of water into the pump, it over stretches the bellows causing them to prematurely crack and leak. The biggest reason is with the drive up the oil in the hydraulic rams can and will settle down either back to the pump or to the bottom of the rams and this causes the seals at the top of the rams to dry out and the rams seize up. This is the most common reason why hydraulic rams are replaced.

Alpha One Generation One pumps with round metal reservoir like an oil filter. These use 1 Phillips screw that goes up through the reservoir to hold the reservoir on. There is a small O ring on the screw and a large O ring on the top of the reservoir. On these the solenoids mount on a plate on the side of the pump and the ground wire goes to the 1/2 inch bolt on the bottom of plate. Also the ground wire from the solenoids goes to that same 1/2 inch bolt. It is easier and standard if on all 2 solenoid Alpha One Generation One, Alpha One Generation Two & Bravo pumps if the top solenoid gets the blue wires for up like sky blue and the bottom solenoid gets the green wires for down like grass.

The Alpha One Generation One, Alpha One Generation Two & Bravo pumps that use a the base to mount the solenoids on use the same configuration with top solenoid blue wires and bottom solenoid green wires. The only real difference is the ground wire goes from the motor and solenoids to the base and of course from the base to the negative on the battery.

The red block on these pumps that the positive wire attaches to is a fusible link and can go bad. So if you are not getting power to the pump it can be the inline fuse, a fuse in your fuse box, a breaker if it is installed or the red block fusible link.

If you ever have a bad solenoid while your out on the water you can jump from the hot lead on the battery to the big blue wire on the motor to get the drive up so you can load your boat on the trailer. I like posting all information on ebay so it can save you money. Boating is oh so much fun but also can cost you oh so much money. If your pump will not work you can disconnect the hydraulic rams from the Outdrive & tie the rams and outdrive up so you can load and transport your boat.

Alpha One Generation One pumps with round metal reservoir like an oil filter. These use 1 Phillips screw that goes up through the reservoir to hold the reservoir on. There is a small O ring on the screw and a large O ring on the top of the reservoir. On these the solenoids mount on a plate on the side of the pump and the ground wire goes to the 1/2 inch bolt on the bottom of plate. Also the ground wire from the solenoids goes to that same 1/2 inch bolt. It is easier and standard if on all 2 solenoid Alpha One Generation One, Alpha One Generation Two & Bravo pumps if the top solenoid gets the blue wires for up like sky blue and the bottom solenoid gets the green wires for down like grass.

The Alpha One Generation One, Alpha One Generation Two & Bravo pumps that use a the base to mount the solenoids on use the same configuration with top solenoid blue wires and bottom solenoid green wires. The only real difference is the ground wire goes from the motor and solenoids to the base and of course from the base to the negative on the battery.

The red block on these pumps that the positive wire attaches to is a fusible link and can go bad. So if you are not getting power to the pump it can be the inline fuse, a fuse in your fuse box, a breaker if it is installed or the red block fusible link.

If you ever have a bad solenoid while your out on the water you can jump from the hot lead on the battery to the big blue wire on the motor to get the drive up so you can load your boat on the trailer. I like posting all information on ebay so it can save you money. Boating is oh so much fun but also can cost you oh so much money. If your pump will not work you can disconnect the hydraulic rams from the Outdrive & tie the rams and outdrive up so you can load and transport your boat.

Diagnostics

All Mercruiser & Mercury pumps use the same wiring diagram. This is a simple pattern. The red wires are all positive/hot wires from battery to pump. The black wires are all negative/ground wires. The blue wires are for up like a blue sky and the green wires are for down like green grass. The blue wires go to 1 solenoid for up and if you have 2 solenoids the green wires go to the second solenoid for down.

In 1983 the US coast guard passed a law that all pumps become 2 solenoid pumps mainly for safety. But a second solenoid for down also increases the down speed as a larger wire is used from solenoids to battery (12 Gauge) and then 14 gauge from dash switch to pump. The positive/hot wire should always be fused or a breaker before it hits the pump.

The number J1171 is on all pumps, starters, carburetors, alternators & distributors! This just means it is coast guard approved anti-spark. J1171 is not and I repeat NOT A SERIAL NUMBER! A lot of sellers put this J1171 number in there title and description in hopes that you think it is a serial number and you buy because it is the correct replacement for your boat. Then the seller does not want to accept a return because you bought the wrong pump!

To test a pump motor all you need to do is make sure the black wire has a good ground and run a red test wire to the big blue or green wire that comes out of the motor. If it does not do anything and not even spark then the motor has gone (no contact on brushes). If it sparks then it could be motor or pump is frozen. But either way it is time to replace.

To test solenoids, the big posts are 1 for positive wire and the other big post to a test light that is grounded. The small posts are 1 ground and the other gets a hot wire. The small posts engage the big posts. It does not normally matter which big post is used for positive in or which small post is used for ground.

Cleaning your pumps, you can do it, but do not totally disassemble your pump. There are a lot of tiny washers, check balls, seals & springs that can fly away. Just take the main pump body off the reservoir and clean. I use a spray can of engine degreaser and hot water to rinse. Then I use rubbing alcohol to dissipate the left over moisture before re-assembling.

Never leave your boat stored with outdrive in up position. With the rams up there is less fluid in the pump reservoir and it will cause condensation of water into the pump, it over stretches the bellows causing them to prematurely crack and leak. The biggest reason is with the drive up the oil in the hydraulic rams can and will settle down either back to the pump or to the bottom of the rams and this causes the seals at the top of the rams to dry out and the rams seize up. This is the most common reason why hydraulic rams are replaced.

International Buyers

Import duties, taxes, and charges are not included in the item price or shipping cost. These charges are the buyer's responsibility. Please check with your country's customs office to determine what these additional costs will be prior to bidding or buying. These customs/duty charges are different for all different countries and sometimes it is

not

applied. You should always consider they will be implemented so you are prepared. I ship everything internationally USPS postal service and I have no idea how it will arrive in your country. Please do NOT ask me to ship as gift or send a lower invoice amount, If you can’t afford your countries duty/customs fees please don’t buy from me. It is illegal for me to ship a paid for item as a gift and I will not lie for anyone and state a lower price.

Please leave us an all 5 star seller rating! If for any reason you feel that you cannot leave us all 5's please contact us and we will do our best to

help

you resolve any problem!